-

Napęd o zmiennej częstotliwości VFD

-

Przetwornica zmiennej częstotliwości

-

Wektorowy przemiennik częstotliwości

-

Przemiennik częstotliwości VFD

-

Przetwornica częstotliwości

-

Przesyłka zmiennej częstotliwości do żurawia

-

Stacja ładowania pojazdów elektrycznych z przechowywaniem energii odnawialnej

-

Optymalizator słoneczny

-

solarny falownik hybrydowy

-

Jake MillerZaryzykowaliśmy z inverters-vfd.com w kwestii krytycznej wymiany VFD na naszej linii montażowej. Produkt był nie tylko idealnie dopasowany, ale także bardziej przystępny cenowo niż u naszego poprzedniego dostawcy. Jego stabilność wyeliminowała nasze częste problemy z wyłączaniem. Wyjątkowa wartość i niezawodny partner w zakresie komponentów przemysłowych.

Jake MillerZaryzykowaliśmy z inverters-vfd.com w kwestii krytycznej wymiany VFD na naszej linii montażowej. Produkt był nie tylko idealnie dopasowany, ale także bardziej przystępny cenowo niż u naszego poprzedniego dostawcy. Jego stabilność wyeliminowała nasze częste problemy z wyłączaniem. Wyjątkowa wartość i niezawodny partner w zakresie komponentów przemysłowych. -

Sarah ChenZespół techniczny z inverters-vfd.com okazał się bezcenny. Opisałam naszą aplikację dla serwomotoru, a oni polecili model o doskonałej reakcji dynamicznej. Instalacja przebiegła bezproblemowo, a precyzja poprawiła czasy cykli. Fachowe doradztwo i produkt o wysokiej wydajności!

Sarah ChenZespół techniczny z inverters-vfd.com okazał się bezcenny. Opisałam naszą aplikację dla serwomotoru, a oni polecili model o doskonałej reakcji dynamicznej. Instalacja przebiegła bezproblemowo, a precyzja poprawiła czasy cykli. Fachowe doradztwo i produkt o wysokiej wydajności! -

David "Big D" KowalskiNasze zamówienie na wiele jednostek PLC i HMI zostało zrealizowane dokładnie i wysłane z zadziwiającą szybkością. Od czasu ich integracji komunikacja naszego systemu sterowania jest bardziej niezawodna. Jesteśmy pod wrażeniem logistyki i solidnej wydajności tych komponentów. Bezproblemowe doświadczenie w każdym calu.

David "Big D" KowalskiNasze zamówienie na wiele jednostek PLC i HMI zostało zrealizowane dokładnie i wysłane z zadziwiającą szybkością. Od czasu ich integracji komunikacja naszego systemu sterowania jest bardziej niezawodna. Jesteśmy pod wrażeniem logistyki i solidnej wydajności tych komponentów. Bezproblemowe doświadczenie w każdym calu. -

Emily WhitePotrzebowaliśmy silnika wrzeciona o niskim poziomie hałasu do wrażliwego środowiska testowego. Zakupiona przez nas jednostka pracuje bardzo cicho i utrzymuje stały moment obrotowy. Jakość przewyższa niektóre znane marki, których używaliśmy, przy ułamku kosztów. Wyjątkowy do specjalistycznych zastosowań.

Emily WhitePotrzebowaliśmy silnika wrzeciona o niskim poziomie hałasu do wrażliwego środowiska testowego. Zakupiona przez nas jednostka pracuje bardzo cicho i utrzymuje stały moment obrotowy. Jakość przewyższa niektóre znane marki, których używaliśmy, przy ułamku kosztów. Wyjątkowy do specjalistycznych zastosowań.

Environmentally Adaptive HD2000 Systems: Operates from -25°C to +65°C and Humidity Up to 85%

Skontaktuj się ze mną o darmowe próbki i kupony.

WhatsApp:0086 18588475571

wechat: 0086 18588475571

Skype: sales10@aixton.com

Jeśli masz jakiekolwiek obawy, oferujemy 24-godzinną pomoc online.

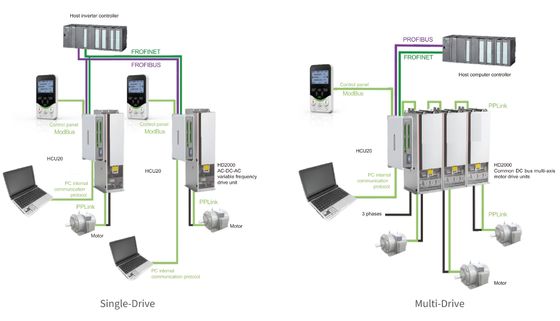

x| Jeden/wiele dysków | Elastyczny system z jednostkami/szafami obsługującymi dwie/cztery ćwiartki | Projekt modułowy | Umożliwia elastyczność aplikacji i kompleksową integrację systemu |

|---|---|---|---|

| Jednostki prostownicze | Jednostki prostownicze Basic/Smart/PWM do wszechstronnej konwersji mocy | Max. Maks. Single Unit Power Moc pojedynczej jednostki | 1400 kW (chłodzony powietrzem), 2800 kW (chłodzony cieczą) |

| Poziomy napięcia | 400 V, 690 V, 1140 V, 1380 V | Max. Maks. Parallel Operation Power Moc pracy równoległej | 11200 kW (chłodzony powietrzem), 22400 kW (chłodzony cieczą) |

| Podkreślić | VFD drive with wide temperature range,Variable frequency drive for high humidity,HD2000 VFD with extreme environment adaptability |

||

| Model | HD2000 Series Low Voltage Engineering Inverter(Liquid-cooled) | |

|---|---|---|

| Basic Rectifier | Input voltage | 4:380V~480V,6:500V~690V |

| Input frequency | (50Hz/60Hz)±6% | |

| Output voltage | Input voltage * 1.32 (Under full-load condition) | |

| Overload capacity | Relative overload at 150% of rated current for 60 seconds, maximum current (Imax), DC overload for 5 seconds,duty cycle of 300 seconds | |

| Operating efficiency | ≥99% Efficiency | |

| Protection eunctions | Protection functions: Overheating protection, soft-start protection, Interlock | |

| protection, and more. | ||

| Intelligent rectifier | Input voltage | 4:380V ~ 480V,6: 500V ~ 690V |

| Input frequency | 47 ~ 63Hz | |

| Output voltage | Input voltage * 1.3 (Under full-load condition) | |

| Overload capacity | Relative overload at 150% of rated current for 60 seconds, maximum current (Imax), DC overload for 5 seconds,duty cycle of 300 seconds | |

| Operating efficiency | ≥98.5% Efficiency | |

| Protection functions | Protection functions: Overheating protection, Overcurrent protection, IGBT pass-through protection, and more | |

| PWM rectifier | Input voltage | 4:380V~480V,6:500V~690V,9:1140V,A:1380V |

| Input frequency | 47 ~ 63Hz | |

| Output voltage | Input voltage * 1.5 (Under rated conditions) | |

| Overload capacity | Relative overload at 150% of rated current for 60 seconds, maximum current (Imax), DC overload for 5 seconds,duty cycle of 300 seconds | |

| Operating efficiency | ≥98% Efficiency (Including LCL filter unit) | |

| Power factor | Adjustable (Factory setting at 1) | |

| Protection functions | Protection functions: Overheating protection, Overcurrent protection, Overload protection, IGBT pass-through protection, and more. | |

| Inversion | Rated Input voltage | 4:410Vdc~780Vdc,6:550Vdc~1100Vdc,9:1488Vdc~2200Vdc, |

| A:1488Vdc~2200Vdc | ||

| Output voltage | 0 ~ Rectifier AC input voltage | |

| Output frequency | 0 ~ 500Hz | |

| Speed range | V/F:1:50 OLVC:1:200 CLVC:1:1000 | |

| Speed stability | OLVC:0.2% CLVC:0.01% | |

| Speed fluctuation | OLVC:0.2% CLVC:0.1% | |

| Starting torque | OLVC:150%(0.5Hz) CLVC:200%(0Hz) | |

| Torque control | V/F: Unsupported OLVC:Supported CLVC: supported | |

| Torque accuracy | OLVC:5% CLVC:5% | |

| Torque response time | OLVC:5ms CLVC:5ms | |

| Speed response time | OLVC:100ms CLVC:100ms | |

| Dynamic speed drop equivalent | OLVC:0.5%*s CLVC:0.3%*s | |

| Environmental conditions | Temperature | -15℃ ~ +40℃ Without derating, +40℃ ~ +55℃ derating applies |

| Humidity | 5% ~ 95% Mon-condensing | |

| Altitude | ≤4000m, Derating applies from 2000m to 4000m | |

| Mechanical data | Anti-vibration performance | Complies with IEC 60721-3-3:2002 |

| Protection level | IP00 / IP20 / IP40 | |

| Safety level | Complies with UL 508C-2004 | |

| Cooling method | Liquid-cooled | |

![]()

![]()

Focus: Industrial Reliability, Energy Efficiency, and Compliance

-

Q: Does the HD2000 VFD meet UL safety standards for industrial use in the U.S.?

A: Yes, the HD2000 series complies with UL 508C-2004, ensuring top-tier safety and reliability for demanding American industrial environments. -

Q: How does the HD2000 help reduce operational costs in manufacturing?

A: With operating efficiency up to ≥99% in basic rectifier models, the HD2000 minimizes energy waste, leading to significant cost savings over time. -

Q: Can the drive handle sudden load spikes common in U.S. factories?

A: Absolutely. It supports 150% overload for 60 seconds and DC overload for 5 seconds, providing robust performance during peak demands. -

Q: What cooling options are available for high-temperature regions like Texas?

A: Both air-cooled and water-cooled models are offered, with operating temperatures up to +55°C (with derating), ideal for varied climates. -

Q: Is the HD2000 suitable for multi-drive systems in large plants?

A: Yes, its modular design supports complex single-drive or multi-drive setups, making it perfect for scalable American industrial applications. -

Q: How does the product ensure long-term durability?

A: With protection functions like overheating, overcurrent, and soft-start, plus anti-vibration compliance (IEC 60721-3-3), it offers exceptional longevity.

Focus: Precision Engineering, Environmental Standards, and High Performance

-

Q: How precise is the speed control in the HD2000 for German engineering applications?

A: With CLVC mode, speed stability is 0.01% and speed fluctuation is 0.1%, meeting the high precision required in German automation and machinery. -

Q: Does the HD2000 support torque control for sensitive processes?

A: Yes, OLVC and CLVC modes enable torque control with 5% accuracy and 5ms response time, ideal for precision-driven industries. -

Q: Is the product compliant with European environmental and safety norms?

A: While explicitly tested to international standards, it aligns with IEC anti-vibration norms and offers IP00-IP40 protection levels for safe operation. -

Q: How efficient is the PWM rectifier under full load?

A: The PWM rectifier achieves ≥98% efficiency (including LCL filter), ensuring energy savings and compliance with German efficiency directives. -

Q: Can the HD2000 operate in variable frequency ranges for specialized equipment?

A: Yes, output frequency ranges from 0 to 500Hz, supporting diverse motor types used in German manufacturing. -

Q: What makes the HD2000 ideal for harsh industrial environments?

A: With wide humidity tolerance (5%-95% non-condensing) and robust protection functions, it performs reliably in challenging conditions.

Focus: Compact Design, High Frequency, and Technology Integration

-

Q: Is the HD2000 available in compact sizes for space-limited Japanese facilities?

A: Yes, compact air-cooled models (5.5–160kW) and modular units allow flexible installation in tight spaces. -

Q: How does the drive support high-speed applications common in Japan?

A: With an output frequency range of 0–500Hz and CLVC starting torque of 200% at 0Hz, it excels in high-speed automation and robotics. -

Q: What protection features prevent damage in frequent start-stop cycles?

A: Soft-start protection, IGBT pass-through protection, and overload capabilities ensure smooth operation and extended equipment life. -

Q: Can the HD2000 integrate with smart factory systems?

A: Yes, the intelligent rectifier and PWM options support advanced control and monitoring, aligning with Japan’s Industry 4.0 initiatives. -

Q: How does the product perform in high-humidity coastal areas?

A: With 5%–95% non-condensing humidity tolerance, it remains reliable in humid climates like Osaka or Tokyo. -

Q: What efficiency levels can we expect for energy-conscious Japanese markets?

A: Efficiencies range from ≥98% to ≥99%, reducing operational costs and supporting sustainability goals.